Model CL3020 NOx Analyzer

Home | Process Monitors | CEMS Gas Analyzers | About Us | Contact

High performance, robust, solid-state chemiluminescence NOx detection make the CL3020 a great alternative to conventional photomultiplier-based NOx analyzers in both process control applications and conventional extractive CEMS.

Options include our integrated oxygen measurement, continuous dual-cell speciation, and ammonia measurement.

Building upon the success of our Model 7705, the Brand-Gaus Model CL3020 NOx Analyzer is the ideal choice for measuring NOx, NO, and NO2 concentrations in the most demanding monitoring applications.

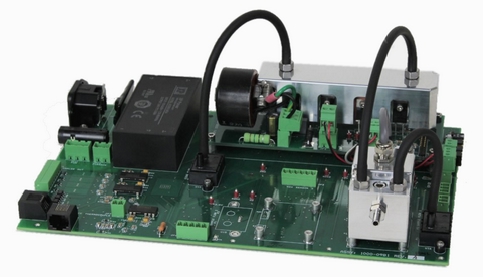

Board mounted NOx detector, ozone generator, and flow meters

Board mounted NOx detector, ozone generator, and flow meters

Analyzer electronics and connectors are on a single electronics board, with ozonator, NOx detectors, power supply, and furnace control components mounted directly on the board

No board-to-board wiring and board-to-connector wiring

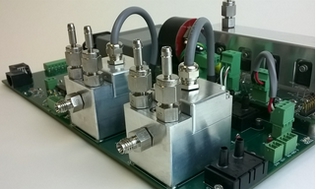

Double-wall glass discharge tube with proprietary external flexible electrode, all encased in a temperature-controlled aluminum block.

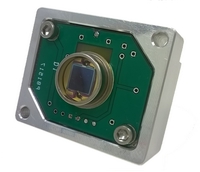

Dual NOx sensors for continuous NO/NO2 measurement

Dual NOx sensors for continuous NO/NO2 measurement

All diagnostics and controls accessible through an advanced, full-color 5” touch screen interface.

Once target gas values (e.g. bottle concentrations) have been entered, span and zero responses may be captured, and hence the analyzer calibrated, at the touch of the screen.

Gas concentrations are plotted in a chart-recorder style trend with user settable scales for in-depth data analysis at a glance.

critical component temperatures and gas flows are measured within the analyzer and reported on the diagnostic screen. Target values and alarmable deviations are user-settable. These alarms are displayed on the home screen, as well as warning messages for internal communication errors or if the converter or ozonator has been disabled.

Each measurement, including dual ranges for NOx, is output as either 4-20mA or 0-10V (user selectable). Analog outputs can be forced to low (4mA/0V) or high (20mA/10V) for troubleshooting. Further, the gain and offset of these analog outputs may be trimmed within approximately +/-5% of full scale to compensate for offsets or other issues with an external the data acquisition system, independent of analyzer calibration.

Analyzer configuration and operating parameters, including calibration settings, can be sent via any mobile device that has a QR code / barcode scanning app for ease in remote troubleshooting and support.

MODBUS over TCP/IP included, allowing access to gas concentrations, diagnostics, alarms, and other instrument parameters. The analyzer is also equipped with a VNC server that allows full remote operation from any device with a VNC viewer connected to the network. Using a locally connected PC or mobile device, factory personnel may remotely inspect and diagnose analyzer problems as if they were standing in front of the analyzer.

| NOx | O2 | |

|---|---|---|

| Measurement technology | Chemiluminescence using all solid-state detection | Amperometric Zirconium oxide cell |

| Measurement range | 0 to 1000 ppm | 0 to 25 %O2 |

| Full scale range | Continuously adjustable from 5 to 1000 ppm | Continuously adjustable from 5 to 25 %O2 |

| Zero noise | < 0.04 PPM | < 0.02 %O2 |

| Zero calibration drift | Better than ± 0.1 PPM | Better than ± 0.1 %O2 |

| Span noise | < 0.25% of reading | < 0.02 %O2 |

| Span calibration drift | Better than ± 1% of reading | Better than ± 0.1 %O2 |

| Linearity error | < 2% of high calibration value across range from zero to full scale | < 1% of high calibration value across range from zero to full scale |

| Response time | T95 < 10 seconds | T95 < 10 seconds |

| NO2 converter efficiency | < 95% |

| Mechanical and Electrical |

|---|

| EIA 19” rackmount enclosure, 11 in. deep, 3 rack units tall (5.25 inches), 24 lbs. |

| Power: 120VAC, 4 Amps max. |

| Sample flow rate: requires approximately 0.1 SLPM at atmospheric pressure (e.g. from a vented sample manifold) per NOx measurement channel |

| Instrument air: requires approximately 0.2 SLPM dry, instrument-quality, oil-free air at atmospheric pressure (e.g. from a vented manifold), per NOx measurement channel |

| Interface Specifications |

|---|

| Isolated Analog Outputs: 4-20 mA maps 0 to full scale concentration |

| Digital communications: MODBUS over Ethernet TCP/IP |

| Remote Control via VNC by mobile or desktop computer |

Home | Process Monitors | CEMS Gas Analyzers | About Us | Contact